38PVC

- Project Start: July 2007

- Project End: July 2007

One of these made it onto a skateboard, and the result was “Rocket Board”.

Casing

- ID: 38.50mm (1.5inch)

- OD: 43.00mm

- Thickness: 2.30mm

- Material: White PVC Pipe

Nozzle

- Throat Diameter: 11.0mm

The nozzle was made from plaster of paris cast inside the PVC pipe. Nozzle is 40mm deep and four 11mm diameter holes where drilled into the PCV pipe surrounding the plaster to provide grip.

End Plug

Cast in exactly the same way as the nozzle.

Propellant

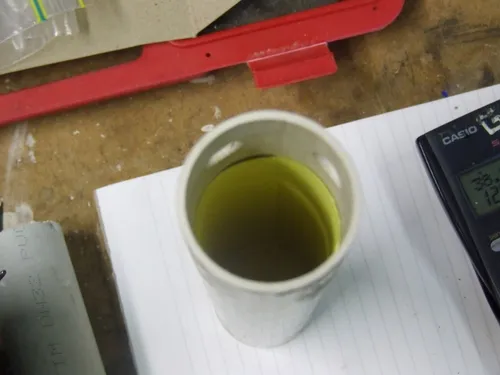

- Composition: 60/40 KNDX

- Weight: 173g

- Grain Length: 135mm

- OD: 33mm

- ID (core): 8mm

A 60/40 mixture of potassium nitrate and dextrose respectively (KNDX). Melted and then cast into mould with centered 8mm diameter metal rod to create a core. Rod coated with Vaseline to prevent it from sticking. Mould made from a length of ID38.5mm PVC pipe (the same as motor), with a sleeve made from two A4 pieces of cardboard rolled up length ways (this reduced OD of propellant grain to 33mm so flame could burn outside). One layer of greased paper was added to prevent propellant sticking. Propellant grain is removed from mould and rod pulled out. All sides of grain (core, both ends, and outside surface) are exposed to flame. Grain is sawn of at both ends to create a 135mm long charge.

Thermal Sleeve

The thermal sleeve consisted of one layer of 0.28mm thick cardboard around the interior of the motor. This was not enough and completely burns out upon firing.

Post Firing Data

- Throat Diameter: 11.5mm

- Throat Expansion: 0.5mm

- Expansion of PVC Pipe: 5.80mm!

- Weight of Motor After Firing: 216g

Inspection

Motor worked successfully and propelled skateboard across the concrete. Average speed over the first second was 40km/h. Burnthrough of PVC pipe occurred 40mm from the nozzle end just where the plaster of paris stopped and the thermal sleeve began. Made a hole 25x3mm and caused the skateboard to do a 360° spin 1.0s into travel. Plaster of paris nozzle was pushed out by 2mm. One of the lugs had snapped of. Nozzle was very close to being blasted out. 4x11mm holes around the circumference of the pipe produced the lugs when the plaster of paris was cast. End cap unharmed. PVC pipe slightly deformed due to heat. PVC pipe was very soft just after firing.

Calculations

38PVC-Rocket-Motor-Data-Richard-Nakkas-SRM.xls

Video

A video of the rocket-board.

Pictures

Click any picture to bring up a gallery view