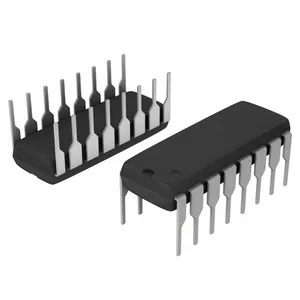

DIP Component Package

DIP is a through-hole component package typically used for integrated circuits (ICs). It is likely the most common through-hole IC package in history, although it is now mostly superseded by SMD packages. It is the lego building block of the component packaging world — and just like Lego, it will destroy your bare feet if you stand on one. It has standard 100mill pitch spacing. The two rows of legs are usually 300mill (thin-type), or 600mill (fat-type) apart (uncommon 400mil and 900mil variants also exist). The 600mill package is usually reserved for the larger pin variants. As well as standard through-hole mounting, they can also be inserted into a socket, either by friction or clamping (zero insertion force). DIP packages usually come with 4-64pins. Pin numbering is counter-clockwise from the top-left.

A common way to denominate the package is by width and the number of pins in the form DIP-<width in inches>-<num. pins>, e.g. DIP-300-8 would be a 300mill wide 8-pin DIP package. If the width is not specified, e.g. DIP-8, assume it is 300mill wide as this is the most common variant.

Anti-static packaging can easily be made for DIP packages with foam and aluminium foil as shown in the picture below.

Components other than ICs can also use this footprint (although they typically have different packages). One example are some 7-segment, 4-digit LCD character displays, which use the DIP-600-12 footprint.

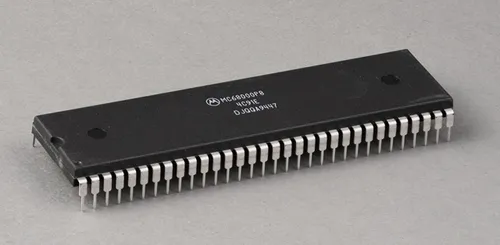

Large DIP packages are unsuitable for high speed devices because of the long length between the internal die and the external pins.

Synonyms

- FDIP (ST Microelectronic’s name for DIP with transparent lid1)

- N Package (Analog Devices)

- DIL (Mitsubishi2)

Variants

- PDIP (plastic dual-inline package)

- CDIP/CERDIP (ceramic dual-inline package)

Soldering

The DIP package is one of the easiest IC packages to solder! Large through-hole pins at a generous 2.54mm (100mil) pitch.

Land Area

The general land area formula for DIP packages is:

where:

is the number of pins

is the rated package width in mm (e.g. 7.62 (300mil), 15.24 (600mil))

The land area for some common DIP packages is:

DIP-300-8: 94.2mm2DIP-300-16: 188.4mm2DIP-300-32: 376.7mm2DIP-600-32: 686.4mm2

3D Models

PDIP

A Plastic Dual Inline Package (PDIP) is a DIP variant in where the case is made from plastic. It typically formed by fusing or cementing the plastic halves around the leads, however it is not considered to be hermetically sealed due to the porous nature of the plastic3.

Transparent Lids

Many EPROM devices in the 1970’s-1980’s were made in a DIP package with a transparent lid. The lid had a transparent section made from quartz which would allow the EPROM to be erased used ultraviolet light (quartz is transparent to many wavelengths of UV lights, whilst many other “clear” materials are not).

Common Uses

- Through-hole ICs

- DIP switches

- Relays/reed switches

- 7-segment, 4-digit LCD character display footprints (with different package)

Similar To

Footnotes

-

ST Microelectronics (2006, April). M27W256: 256 Kbit (32Kb x 8) Low Voltage UV EPROM and OTP EPROM (datasheet). Retrieved 2021-12-28, from https://www.st.com/resource/en/datasheet/cd00004936.pdf. ↩

-

Mitsubishi. M5L2764K 65536-bit (8192-word by 8-bit) Erasable and Electronically Reprogrammable ROM (datasheet). Retrieved 2021-12-27, from https://pdf1.alldatasheet.com/datasheet-pdf/view/126049/MITSUBISHI/M5L2764K.html. ↩

-

Wikipedia. Dual In-line Package (DIP). Retrieved 2021-12-28, from https://en.wikipedia.org/wiki/Dual_in-line_package. ↩