IDC Connectors

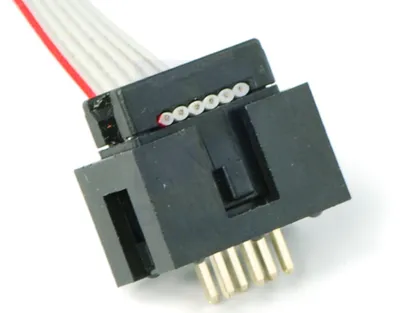

IDC (insulation displacement connector) connectors are very common style of connector used to carry low speed communications and low current power between multiple circuit boards and between circuit boards and other devices. They are distinguishable by the typically black, square and sharp edged connectors, with a ribbon cable coming out the side.

The namesake comes from the way the connector attaches to the ribbon cable --- the connector has sharp “razor” style blades with a notch cut through the center of each one. The ribbon cable is pushed onto the end of the blades, and the blades pierce the ribbon cable and make contact with the blades (hence “displacing the insulation”). This removes the need to strip the end of the ribbon cable and connect via crimps/soldering/screw terminals and thus makes them extremely easy to construct.

Sometimes jokingly referred to as “It Did not Connect” connectors, they can make for unreliable connections when hand assembled or not constructed in the correct manner. Unlike terminal blocks or crimped connectors, it is hard to visually confirm that the connections were made correctly given the clamp obscures the connection points.

The socket (least-moving piece, the side that gets soldered onto a PCB) is shrouded and keyed to make sure the parts mate in the correct way.

A 2.54mm pitched (w.r.t to the pins) IDC connector has two rows of pins, this requires that the flat cable has a conductor pitch of 1.27mm (0.05”).

Some IDC connectors come with built-in strain relief. This is usually in the form of a clip which sits ontop of the connector. The cable is brought out of the insulation displacement part and then curled back around to be clamped by the clip. Strain relief is more common on the 2.54mm pitch IDC connectors, and not so much on the 1.27mm pitch IDC connectors. This can be a problem for longevity of these smaller 1.27mm IDC connectors, which are commonly used for 10-pin ARM SWD programming headers.