Soldering

Manually Applying Solder Paste

Plastic syringe tips are usually better than metal ones, as they offer less friction to the paste, making it easier to control the amount of paste which comes out.

Solder Paste Dispensing Machines

If you are applying solder paste by hand (as opposed to using a template), you can purchase machines which help automatically dispense a measured amount of solder paste from the syringe. Most are operated with air pressure and require an external air compressor (recommended to be at least 1.5HP). You can also get based around linear motors and peristaltic pumps. Common models from AliExpress include:

- YDL-983A

- AD-982

| Model Number | Features | Vendor | Vendor Price |

|---|---|---|---|

| xxx-982 | Analogue dials | AliExpress | US$70 (inc. shipping) |

| xxx-983A | Digital dials | AliExpress | US$120 (inc. shipping) |

Pre/Post Soldering Heaters

Many components require controlled pre-heating and post-cooling to solder effectively.

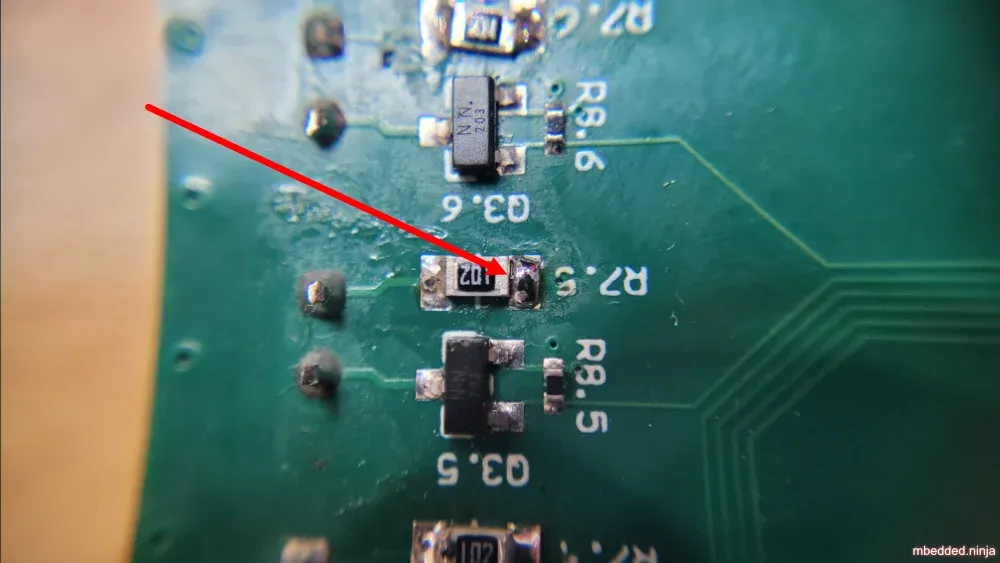

Soldering Defects

Open Circuits

Sometimes when soldering components, especially small ones by hand, you can end up with solder joints that look connected, but are actually open circuits.

Tombstoning

TODO: Add info.

Head-In-Pillow (HiP)

AIM Solder has a great paper on head-in-pillow defects at https://aimsolder.com/sites/default/files/head-in-pillow_bga_defects.pdf (cached local copy).