Boost Converters

Schematics

Boost converters use a switching element, inductor, diode, and capacitor to convert an input voltage into a higher or equal output voltage .

Design Procedure

Duty Cycle

The duty cycle for a boost converter is given by:

As you can see, the duty cycle is dependent only on the ratio between the input and output voltages. This has to be one of the simplest boost converter equations. This equation ignores the specific voltage drops across the switching element and rectifier, but rather lumps them together into the efficiency term.

Inductance

The inductance can be determined using:

You don’t know or yet, but the trick is here to assume a maximum inductor ripple current as a percentage of the average inductor current, . A rule-of-thumb is to assume a maximum ripple current of 35% (assuming it is operating in CCM mode). Thus,

Now the equation for the inductance becomes:

which can be solved as we know all of the variables.

Output Current

The maximum output current is given by:

Diode Selection

The maximum reverse voltage of the diode must be at least equal to the output voltage of the boost converter. This is because diode sees the full load voltage when the switch is closed (in a reverse-biased setup).

PCB Routing

The same rules apply for routing boost converters as with any SMPS. See the PCB Routing section on the SMPS page for more information.

Light Load Instabilities

Bad things can happen when boost converters are operated with light/no load. If the controller isn’t smart enough to reduce the duty cycle down to near 0 when there is no or little load, the voltage across the capacitor can build up to a point where it causes damage to part of the circuitry.

Also, if the converter is in DCM and the load current suddenly increases, the output voltage can sag greatly.

Turning Off/Disabling

While most boost controllers have an enable/disable pin, this doesn’t actually disconnect the input from output, as the switching device is not in series with input and output, as it is in a buck Converter. Thus if you need the load completely disconnected from the input, you will need to add something like a P-Channel MOSFET or load switch to the front-end of the boost converter.

Start-up vs. Runtime Minimum Input Voltage Requirements

Some boost converters have differing start-up and runtime minimum input voltage requirements. Typically, the boost converter requires a higher minimum input voltage to start (e.g. 18V), but once running, can run of a lower voltage (e.g. 500mV).

Bypass

Some boost converters designed for ultra-lower power applications have a bypass mode. When the output voltage is not needed to be higher than the input voltage, the converter enters a bypass mode in where most of the control circuitry is disabled, the converter stops switching, and the input voltage is “bypassed” straight to the output.

Max. Current Ratings

One gotcha: The “max. current” rating that a manufacturer will provide with a boost controller with an integrated switch will usually be the maximum current rating of the switch. This is not the maximum output current, but rather the maximum input current. The maximum output current, assuming you have a higher output voltage, will be less than this.

Compensation Loop

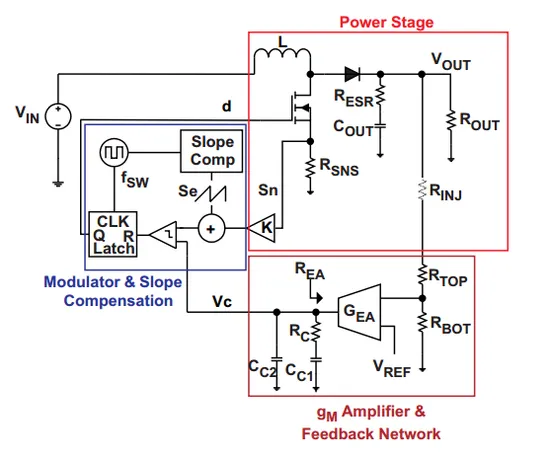

The compensation loop is part of the feedback mechanism. The below diagram shows a current-mode controlled boost converter with a transconductance amplifier () providing the feedback.

The above model is only valid for when the boost converter is acting like a current-mode controlled regulator. This is the case when the ripple current is within the normal operating region (0.2-0.4 times the average input current). When the inductor is oversized to further reduce current ripple through the inductor (less than 0.2 times the average input current), the boost converter behaves more like a voltage-mode controlled regulator and this above model is no longer valid.

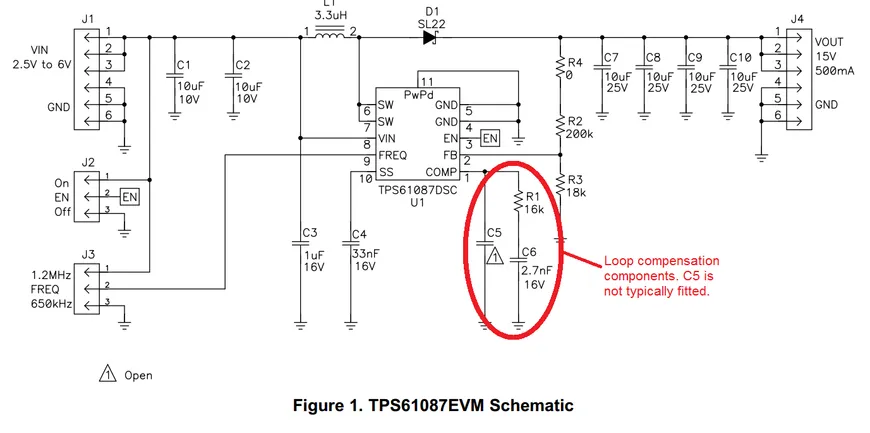

External compensation can be added if the manufacturer provides a compensation pin (typically called COMP). The pin is the output of the internal transconductance amplifier.

A resistance between 5-100kR and a capacitance between 1-10nF is typical. A higher resistance corresponds to a faster response time. A lower capacitance corresponds to a higher phase margin.

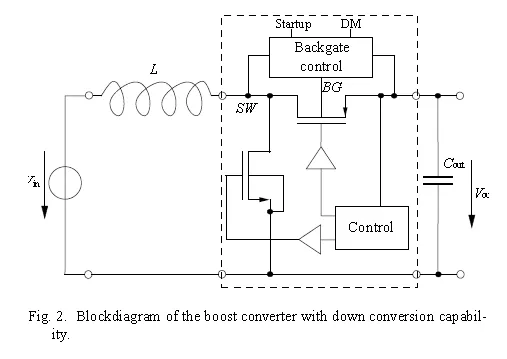

Down Conversion

Some boost converters also have a built in regulator to provide regulation when the input voltage exceeds the desired output voltage. This is normally a linear regulator, so your efficiency will drop and you will have to take into account the thermal dissipation. This is normally called down conversion.

The price you pay for this added down conversion feature is a slightly higher cost, and slightly higher quiescent current (e.g. some of TI’s boost converters have 19uA quiescent current without down conversion, and 25uA with down conversion).

Input Voltage Range

Typically, boost ICs with an internal switch (a converter) can support lower input voltages than those that require an external switch (a controller). A typical minimum input voltage for a converter is in the range 0.3-0.9V, while a controller’s minimum is in the range 0.9-1.8V.

EMC

The output current loop “hot loop” of a boost converter is the most important part to worry about when it comes to EMC. See the EMC Design Guidelines page for more information.